Shougang Jingtang Company

Jun 16,2025

I. Experimental Units: Shougang Jingtang Company and Tangshan Heyuan Steel Pipe Co., LTD

Ii. Experimental Content: Double-sided Submerged Arc welding experiment of Stainless Steel Composite plates

Iii. Test Time: July 26, 2022

Iv. Experimental Location: Tangshan Heyuan Steel Pipe Co., LTD

V. Participants in the Experiment: Wang Fenghui (Doctor), a technical engineer from Shougang; Wang Xiaoxia (Master), a technical engineer from Shougang; Liu Lei from Shougang; Zhang Zhen, General Manager of Heyuan; Geng Yanfeng, Deputy General Manager of Heyuan; Liu Longfei, Zhao Yi, and Dong Shuqiang, technical personnel from Heyuan

Vi. Welding Process

Double-sided submerged arc welding tests were carried out using 5+1mm thick Q235B+304 composite plates. The welding assembly, welding parameters (current, voltage, welding speed, etc.) and welding process were debugged and optimized. The pipe manufacturing and welding of the composite pipes with three parameters were successfully completed. The weld bead was well formed, and no problems such as weld penetration and porosity occurred.

1. Welding test

Table 1 presents the process parameters of the welded test plate, among which the stainless steel side welding material is a 309 submerged arc with a diameter of φ3.2mm

Welding wire +601 flux, for the carbon steel side, the welding material is 10Mn2 welding wire with a diameter of φ3.2mm +101 flux. Figure 1 shows a photo of double-sided submerged arc welding.

Table 1 Process Parameters of the welded test plate

Number | Stainless steel side | Carbon steel side | ||||||||

Number | Current /A | Voltage /V | Welding speed /mm/min | Remarks | Number | Current /A | Voltage /V | Welding speed /mm/min | Remarks | |

1 | 1-2 | 340-360 | 34 | 800-850 | The tail is raised and the arc is broken | 2-1 | 460 | 34 | 800-850 | Good |

2 | 1-3 | Good | 2-2 | 480 | Good | |||||

3 | 1-1 | Good | 2-3 | 500 | Good | |||||

2. Joint analysis

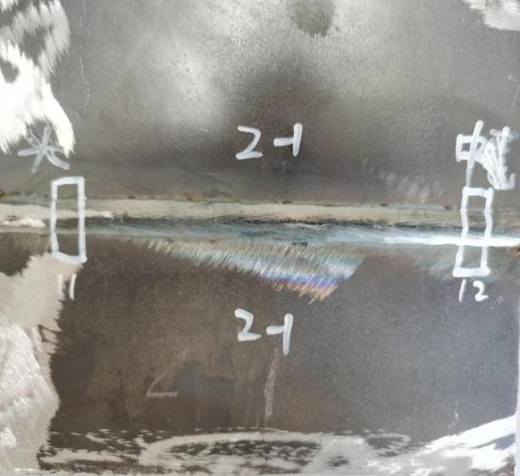

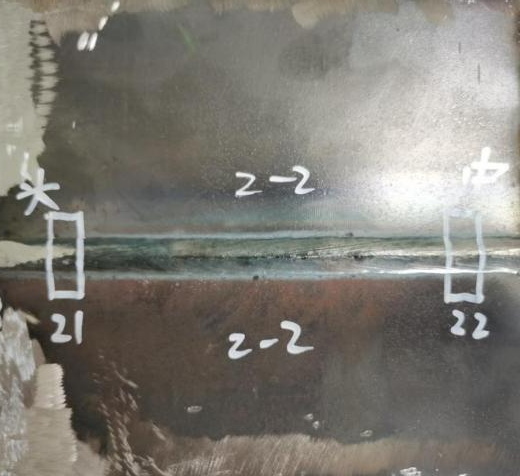

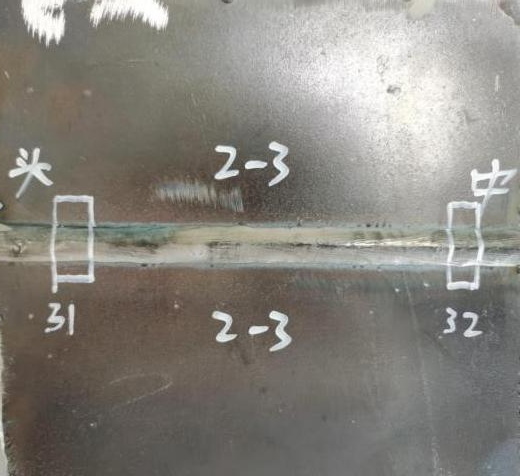

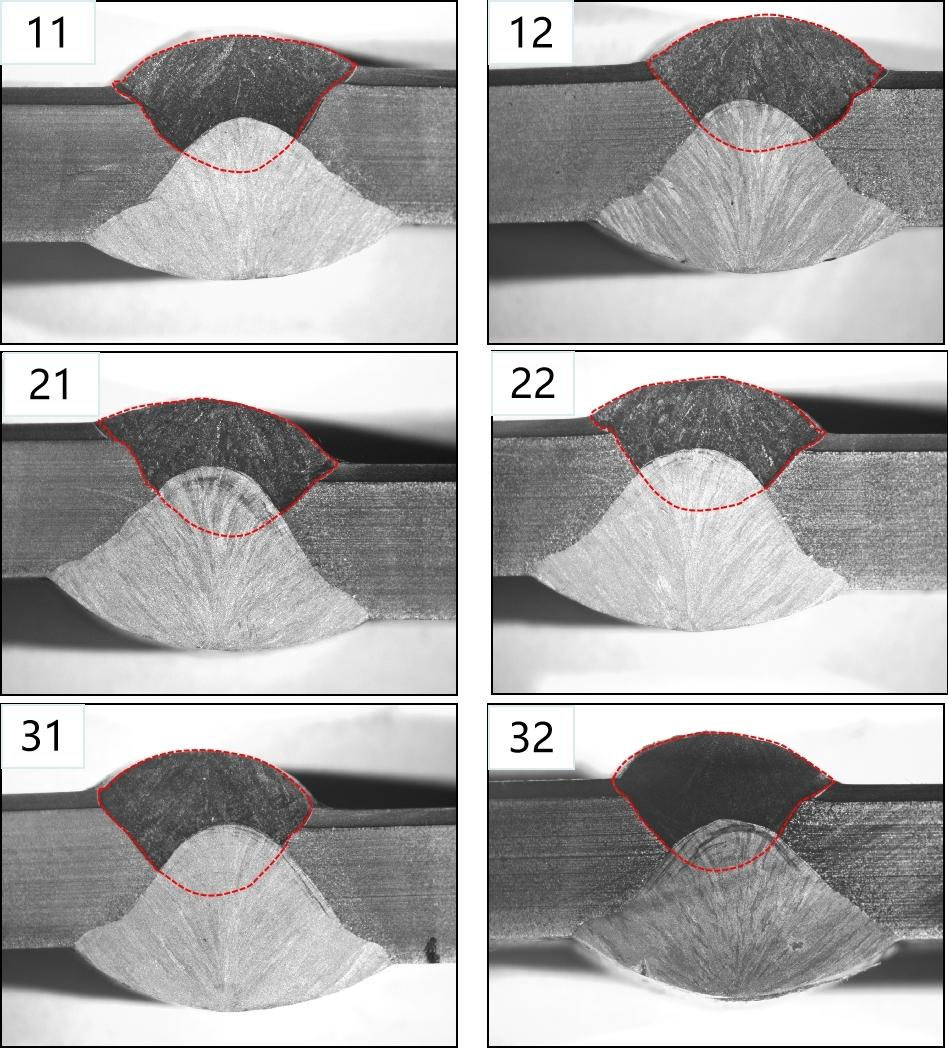

After welding, the appearance and cross-section metallographic of the test plates of the three schemes were inspected. Figure 2 shows the morphology of the weld bead in the three schemes, Figure 3 shows the metallographic structure of the cross-section of the weld bead in the three schemes, and Figure 4 shows the metallographic structure of the stainless steel weld bead. Table 2 presents the measurement results of the weld bead size.

The appearance of stainless steel side weld beads and carbon steel side weld beads

Figure 1 Photo of double-sided submerged arc welding

Figure 2 shows the morphology of the weld beads in the three schemes

Test Board No. 1

|  |

Test Board No. 2

|  |

Test Board No. 3

|  |

Table 2 Measurement Results of weld bead Dimensions /mm

Number | Stainless steel Weld bead depth | Two weld beads Intersection depth | Carbon steel Weld bead depth | Stainless steel Weld bead allowance height | Carbon steel Weld bead allowance height | Stainless steel Weld bead penetration depth |

11 | 5.3 | 2.1 | 6.3 | 1.2 | 1.5 | 4.0 |

12 | 5.3 | 2.0 | 6.7 | 1.8 | 1.8 | 3.5 |

21 | 5.3 | 2.7 | 7.2 | 0.8 | 1.2 | 4.5 |

22 | 5.1 | 2.4 | 7.1 | 1.5 | 1.6 | 3.6 |

31 | 5.6 | 2.7 | 7.2 | 1.6 | 1.8 | 4.1 |

32 | 5.3 | 2.0 | 7.0 | 1.8 | 2.3 | 3.5 |

Figure 3 shows the metallographic cross-section of the weld bead in the three schemes

As can be seen from Figure 3, the weld passes under the three schemes intersect well, and the excess heights of the two weld passes are moderate.

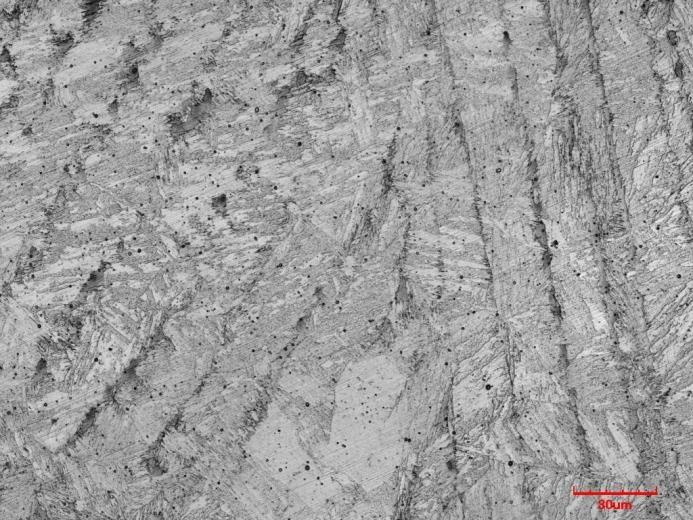

The metallographic structure of the stainless steel weld bead was observed, and the content of the main elements at different positions of the welded joint was detected. Figure 4 shows the metallographic structure of the stainless steel weld area, and Table 3 shows the element content at different positions of the welded joint.

Table 3 Composition of welded Joints at Different Positions

Location | C | Si | Mn | Ni | Cr |

304 lamination | 0.035 | 0.44 | 1.02 | 8.17 | 17.68 |

Stainless steel weld bead | 0.084 | 0.20 | 0.94 | 6.16 | 11.04 |

Carbon steel weld bead | 0.12 | 0.46 | 0.67 | 0.84 | 1.56 |

Figure 4 Metallographic structure of the stainless steel weld zone

As can be seen from Table 3, the stainless steel weld bead is diluted by the base carbon steel, and the content of Ni and Cr elements in the weld bead is lower than that of the laminated 304 stainless steel. There is a risk of priority corrosion in later service, and the weld material needs to be adjusted. Figure 4 shows that the stainless steel weld bead acquires a martensitic structure, which is different from the typical stainless steel weld microstructure (austenite plus a small amount of ferrite structure).

3. Summary

(1) This double-sided submerged arc welding process can achieve the welding of 5+1mm thick composite plates and has a certain welding window.

(2) The size of the stainless steel weld bead in this test is moderate. Under the condition of excellent processability of the welding material, the welding speed can be appropriately increased to 900-1000mm/min.

(3) The weld size of the carbon steel in this test is slightly larger, and the welding current can be reduced to 440A.

(4) The composition of Cr and Ni elements in the stainless steel weld bead obtained by using 309 stainless steel wire is lower than that of the 304 laminated layer, posing a risk of corrosion, and the welding material needs to be adjusted.

(5) The test plates welded last week were analyzed, which proved that there was no problem with the fusion of the two weld beads.

PREVIOUS:

NEXT:

Related News

Contact Us