Contact

Spiral Pipe

It is welded by double-sided submerged arc welding process, with pipe diameters ranging from DN200 to DN4000, wall thicknesses from 5 to 20mm, and materials including Q235B, Q355B, Q355C, 345NS, 345NH, etc. The product features a stable spiral weld structure, high compressive strength, and strong corrosion resistance. It is widely used in oil and gas transportation, urban water supply and drainage networks, large-scale steel structure supports and other projects. According to customer requirements, it can provide shot blasting, sandblasting, anti-corrosion (such as 3PE, epoxy coal tar pitch), insulation treatment, packaging and other services.

Key words:

Spiral Pipe

Classification:

Description

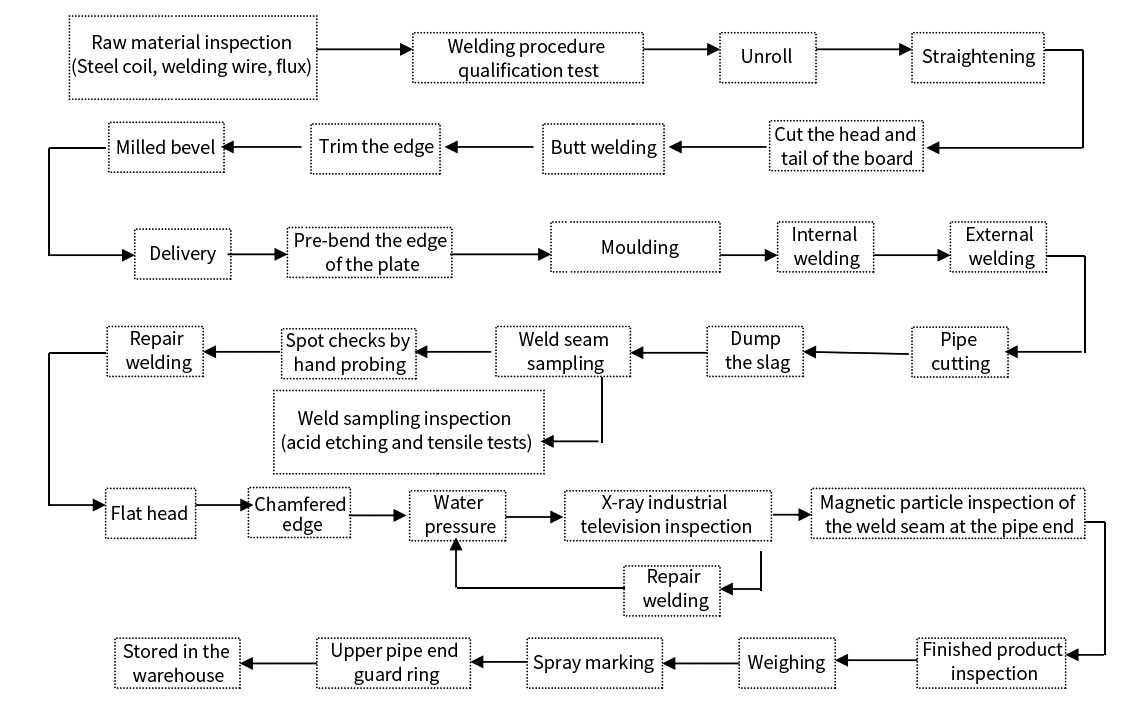

GB/T3091-2015 Process Flow of Steel Pipes for Pipeline Transportation Systems in the Petroleum and Natural Gas Industry

Explanation:

1. Welding procedure qualification: Matching of three major raw materials and selection of welding parameters;

2. Weld sampling: Fracture toughness test, metallographic inspection, tensile test, forward and reverse bending test;

3. The entire weld seam shall undergo ultrasonic inspection, radiographic inspection within 203mm from the pipe end or X-ray inspection throughout the entire length, and magnetic particle inspection at each pipe end after water pressure.

4. Conduct hydrostatic tests on each one;

5. Quality control points: a. Delivery line; b. Trimming luminosity c. Formed pipe diameter, misalignment; d. Weld seam, fusion, porosity, crack, weld deviation; e. Bevel Angle, blunt edge, and bevel; f. Hydrostatic test pressure and holding time: 5 to 15 seconds.

About us

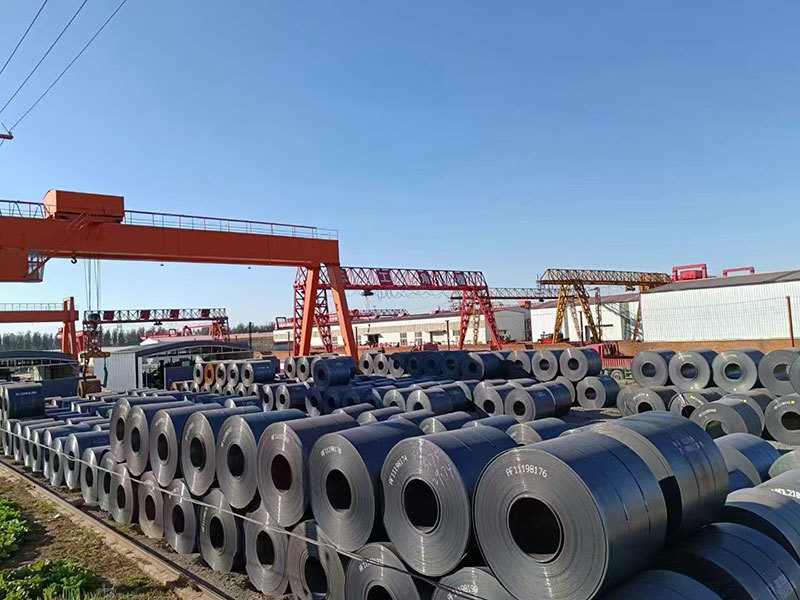

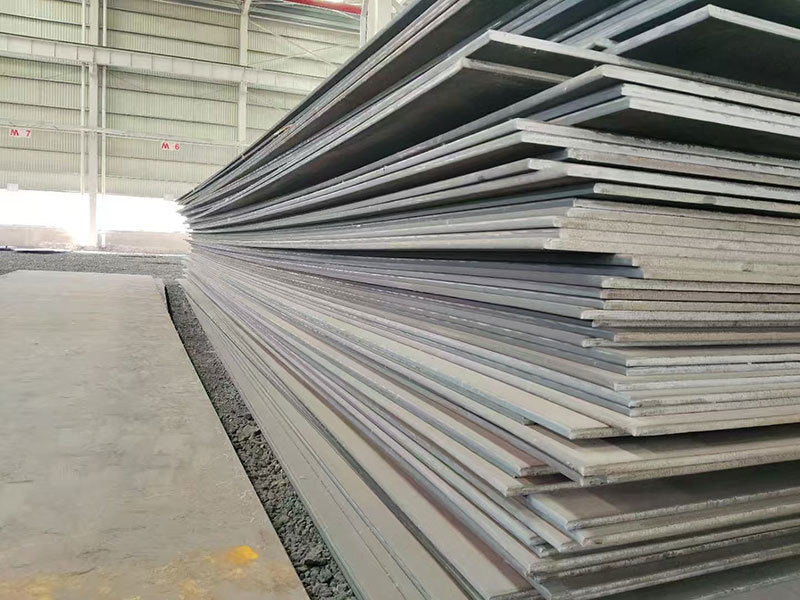

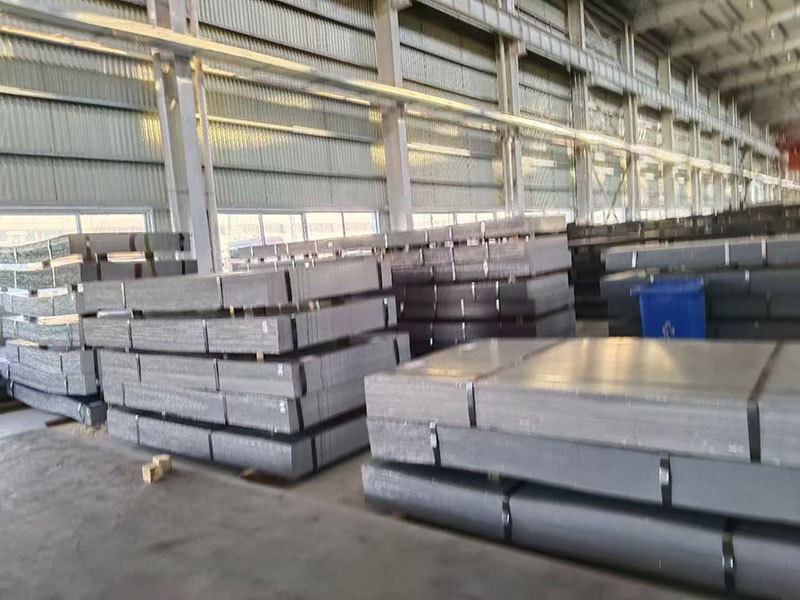

Tangshan Wenwu Trading Co., Ltd. was established in 2010, is a professional company focused on the trade of steel products.The company is headquartered in Tangshan, Hebei. With its superior geographical location and convenient transportation network, it is closely connected to major steel production bases and markets across the country and even around the world. It has rich experience and excellent reputation in the fields of spiral steel pipes, straight seam steel pipes, coils and steel plates.

The company has established long-term and stable cooperative relations with a number of large steel production enterprises at home and abroad to ensure product quality and timeliness of supply.At the same time, the company has a professional quality inspection team, which strictly controls the quality of each batch of products to ensure that they meet national and international advanced standards.

The company has an experienced and professional foreign trade team. Its members are proficient in multiple languages, familiar with international market rules and trade processes, and can provide customers with efficient and high-quality services.Relying on its keen insight into the market and good customer relationship management capabilities, the team continues to explore new markets to meet the individual needs of customers.

The company pays attention to the efficiency and safety of logistics and distribution, and has established long-term cooperative relations with a number of well-known logistics companies to ensure that steel products can be delivered to customers in a timely and accurate manner.In addition, the company also provides perfect after-sales service and has set up a special after-sales service team to deal with the problems encountered by customers in the process of using the products in a timely manner, with customer satisfaction as the guide, and continuously improve the quality of service.

In the future, Tangshan Wenwu Trading Co., Ltd. will continue to uphold the business philosophy of “integrity management, quality first, customer first”, continuously optimize product structure, improve service level, and strive to become a leading enterprise in the field of foreign trade in the global steel industry, and make greater contributions to promoting the development of global steel trade.

Strength

Related Products

Pre

Next

Consultation

Please leave your contact information and we will get back to you as soon as possible